solidworks flow simulation heat transfer

Ill right-click Goals select Insert Global. Of the 3 modes of heat transfer conduction convection and radiation radiative transfer is perhaps the most overlooked in simulation.

Solidworks Flow Simulation Transient Natural Convection Solidworks Simulation Flow Training

Heat transfer analysis in the 3D CAD environment.

. With integrated CFD you can accurately predict product performance as it relates to fluid flow airflow and aerodynamics as well as heat transfer and cooling. Learn the basics on how t. This is an internal analysis with default outer wall condition heat transfer coefficient 7wm2K.

SOLIDWORKS Flow is a specialized application for simulating fluid flow and heat transfer. In particular the capability of EM radiation to transmit heat energy. With the full SolidWorks Flow Simulation product you have the following advanced functionality.

SOLIDWORKS Flow Simulation gives you powerful fluid flow analysis tools directly in your 3D CAD interface and offers easy automated test setup and quick feedback. Heat transfer issues can be exceedingly difficult and often impossible due to the obstacles. Hello Im new in flow simulation.

We will mix hot and cold water in soliworks flow simulation t. LM By Lukas Müller 022116. Specify different types of heat sources.

The last thing to do before running the project is to define the goals. I decided to go into a bit more detail in this blog about the basics of radiative heat transfer in SOLIDWORKS Flow Simulation. Some of the topics covered include.

With the exception of very few scenarios when considering a thermal analysis solver for SOLIDWORKS you should choose to use Flow Simulation which is a computational fluid dynamics CFD code. I dont define any temperatures nor any heat flows. Simulate heat transfer coefficient.

Air or liquid flow is a critical part of keeping any electronics properly cooled this video shows how Flow Simulation handles both aspects of such problems. From the Flow Simulation menu Ill select Insert Surface Source. Hi all I like to simulate the heat transfer coefficient for a specific flow simulation problem.

To-use fluid-flow analysis application like SOLIDWORKS Flow Simulation software you will have the tools that you need to solve even the most difficult heat transfer problems while saving time and money in the process. A surface source can be used to generate heat at the top of the plate. For our heat source we.

Set additional parameters that control how the analysis resolves the solidfluid interface curved surfaces narrow channels small solid features etc. As you may already know there are three modes of heat transfer. Conduction convection and radiation.

I have been asked a few times about calculating and applying a convection boundary condition for SOLIDWORKS Simulation Thermal analyses because without a CFD software like SOLIDWORKS Flow Simulation convection must be calculated by hand. You can apply these settings globally or for assemblies to a. Next we need to check the box next to Heat Sources to add it to the tree.

Im trying to simulate an assembly with a duct and a heat sink. Calculate heat flow in the adiabatic walls approximation or in solid bodies. In this tutorial We will learn how to Do heat transfer analysis in solidworks flow simulation.

After the simulation is finished I can get the values for the heat transfer coefficient. For the selection well choose the four burner faces mentioned earlier. I have an assembly in Solidworks 2010 and I am trying to simulate heat transfer throughout the component using the Simulation tool.

This allows engineers to use the resulting force and heat transfer effects from their CFD analysis as the load inputs in their FEA analysis to fully understand the structural behavior based on fluid behavior. Because SOLIDWORKS incorporates CFD analysis and FEA designers can incorporate both with the FEA transfer from SOLIDWORKS Flow Simulation. Basically I want to heat the top of the component at 210 C and then allow heat to flow through the component and then radiate to the external atmosphere say at 25 C.

Assign to models a broad range of solid materials that are stored in the engineering database. For thermal heat transfer analysis choose SOLIDWORKS Flow Simulation over the Thermal solver in Simulation Professional Part 3 of 3 Meshing. SOLIDWORKS Flow Simulation can improve design productivity and may dramatically reduce the number of physical prototypes needed for testing.

Set the initial temperature of a solid. To start well right click on the project and select Customize Tree. Equally important it encourages engineers to explore many more what-if scenarios to perfect their designs.

The heat sink is inserted in the duct by the part of the fins in order to capture the heat flow through the duct. I am doing this in order to see how long it. Ill select the top surface of the plate and enter a Heat Generation Rate of 200 W.

This question has a validated answer. Next well right-click on Heat Sources and select Insert Surface Source.

Solidworks Flow Simulation Transient Manifold Airflow Solidworks Industrial Design Sketch Solidworks Tutorial

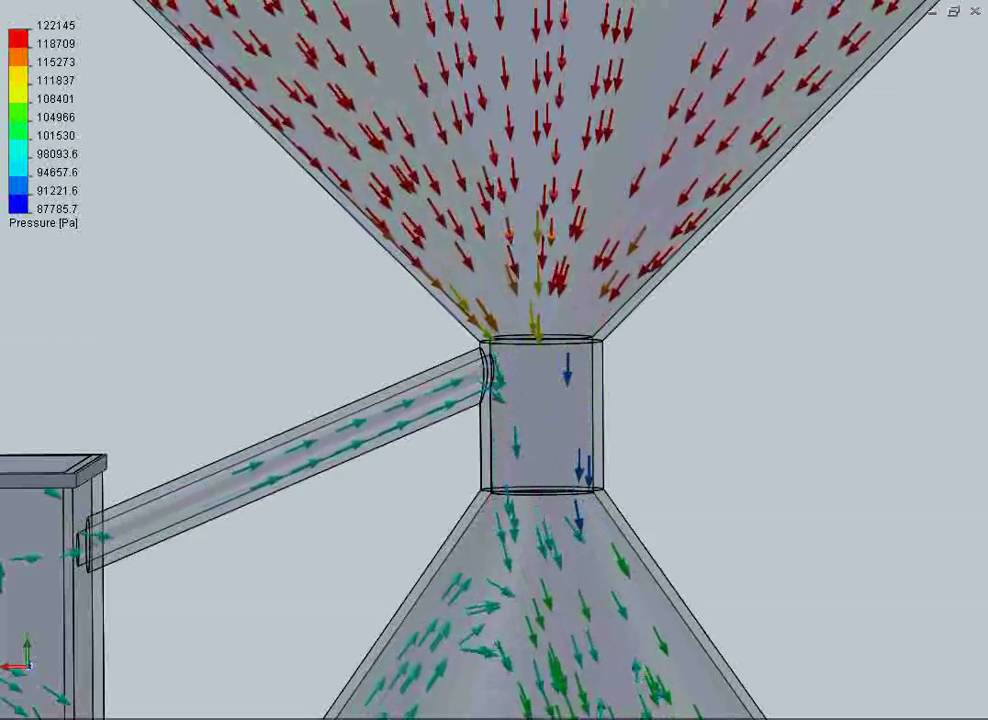

Solidworks Flow Simulation Venturi Effect Animation Fluid Mechanics Physics Topics Venturi

Thermal Effects In Cfd Tool In Solidworks Flow Simulation Http Blogs Solidworks Com Solidworksblog 2013 10 Relax And Reduce Hair Loss We Have The Solution Fo

Suction Pump Simulation Using Flow Simulation Solidworks Tutorial Solidworks Simulation

Cfd Simulation Of Water Purification Process Simscale Water Purification Process Cfd Simulation Water Purification

Pin On Solidworks Advanced Tutorials

Software Cfd Criacao De Simulacoes De Fluidodinamica Cfd Simulation Simulation Solidworks Tutorial

We Offer Heat Transfer Analysis Services To A Large Range Of Industrial And Manufacturing Co Computational Fluid Dynamics Cfd Simulation Environmental Analysis

Flow Simulation Heat Exchanger

Thermofluid Analysis Of A Heat Exchanger Ansys Heat Exchanger Computational Fluid Dynamics

Introduction To Solidworks Flow Simulation Solidworks Mechanical Design Simulation

Effect Of Boundary Condition In Thermal Analysis Using Ansys Analysis Ansys Structural Analysis

Solidworks Flow Simulation Solver Window Solidworks Domain Knowledge Simulation

Faheemfiaz8 I Will Do The Cfd Analysis With The Help Of Ansys Fluent For 30 On Fiverr Com Ansys Cfd Simulation Service Design

Pin On Computational Fluid Dynamics Cfd

Easily Simulate Fluid Flow Heat Transfer And Fluid Forces That Are Critical To The Success Of Your Design With Solidworks Flow Simulation Contact 91 Scherma

Flow Simulation Of A Waterfall Fluid Flow Computational Fluid Dynamics Waterfall